Supply Chain Planning

Boosting your supply chain has never been easier

Software de planificación de demanda, producción y compras. Una herramienta sencilla y rápida de planificación de demanda con la que todo tu equipo querrá trabajar. Mejora tus previsiones. Optimiza tu servicio. Incrementa tus ventas.

Con Supply Chain Planning planifica mejor, reduce inventarios y aumenta beneficios

Líderes en SCM software

Expertos en estandarización de todos tus procesos de planificación con las mejoras prácticas del mercado.Desde 350€/mes

Una solución al alcance de todas las empresas que se adapta y crece según tus necesidades específicas.100% Customer fit

Construye tu propia herramienta y amplía su funcionalidad a través de nuestro marketplace de plugins.Nuestra solución Supply Chain Planning All-in-One SaaS

- All-in-One Sass

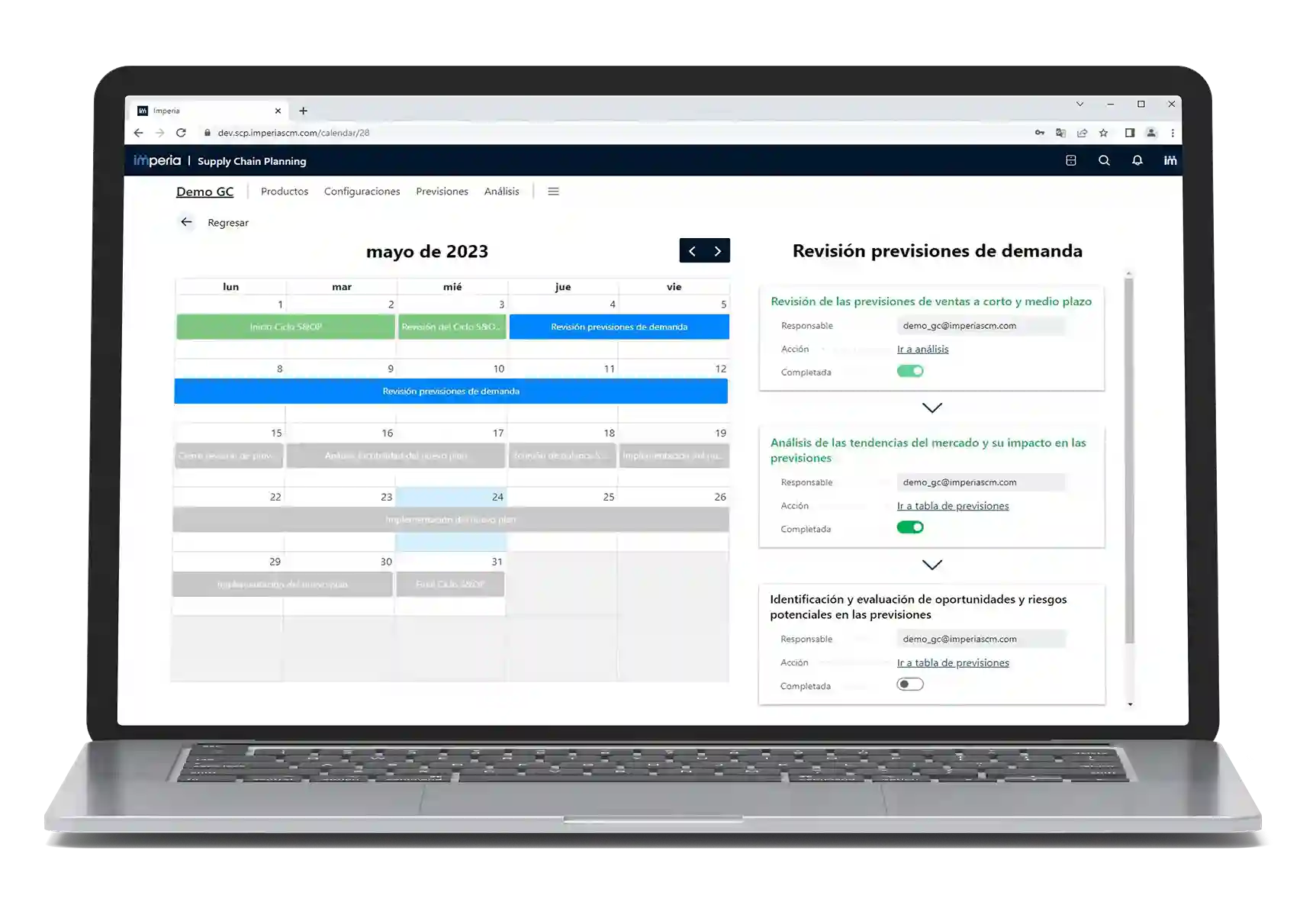

- Ciclo S&OP / IBP

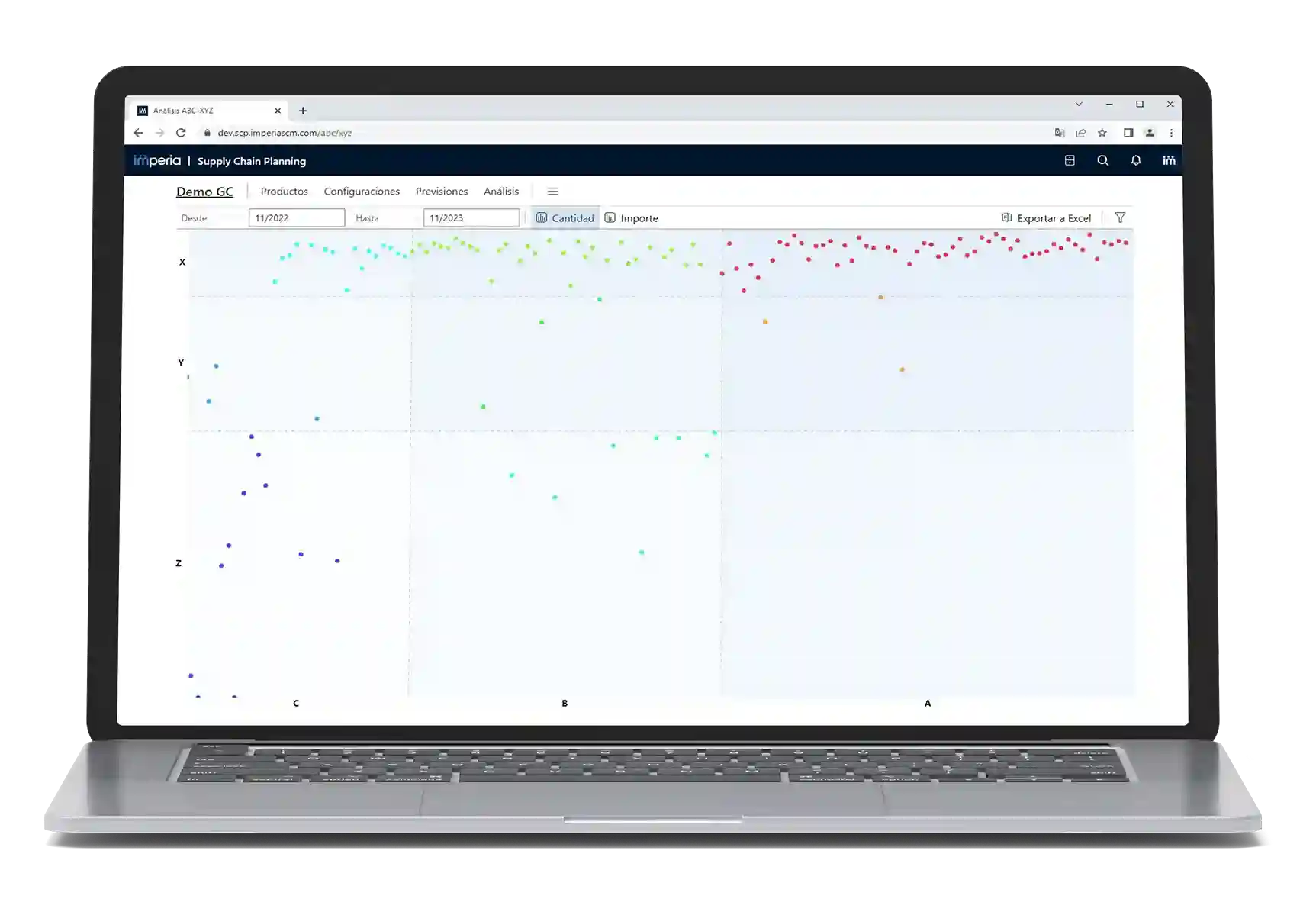

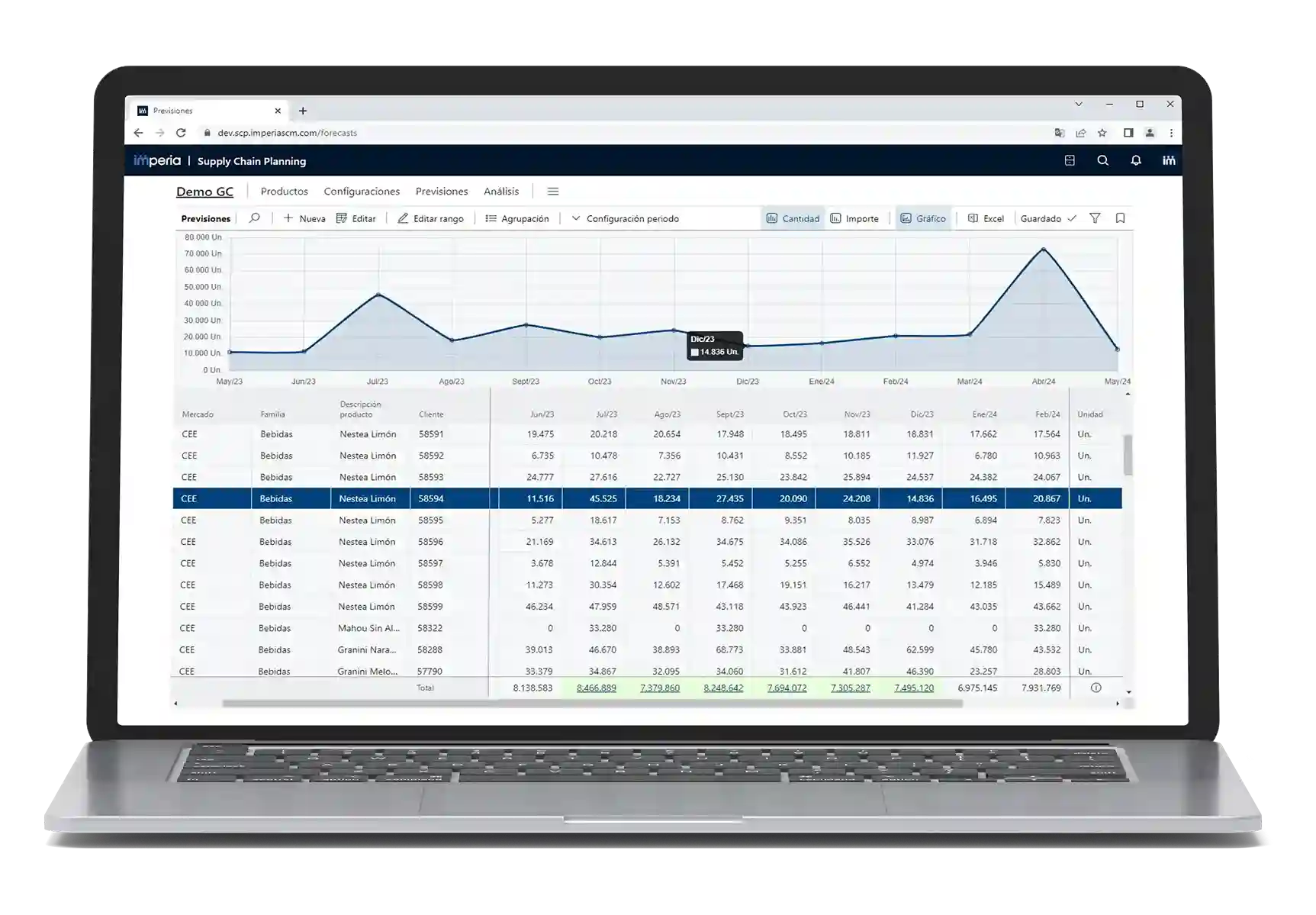

- Demanda

- Producción

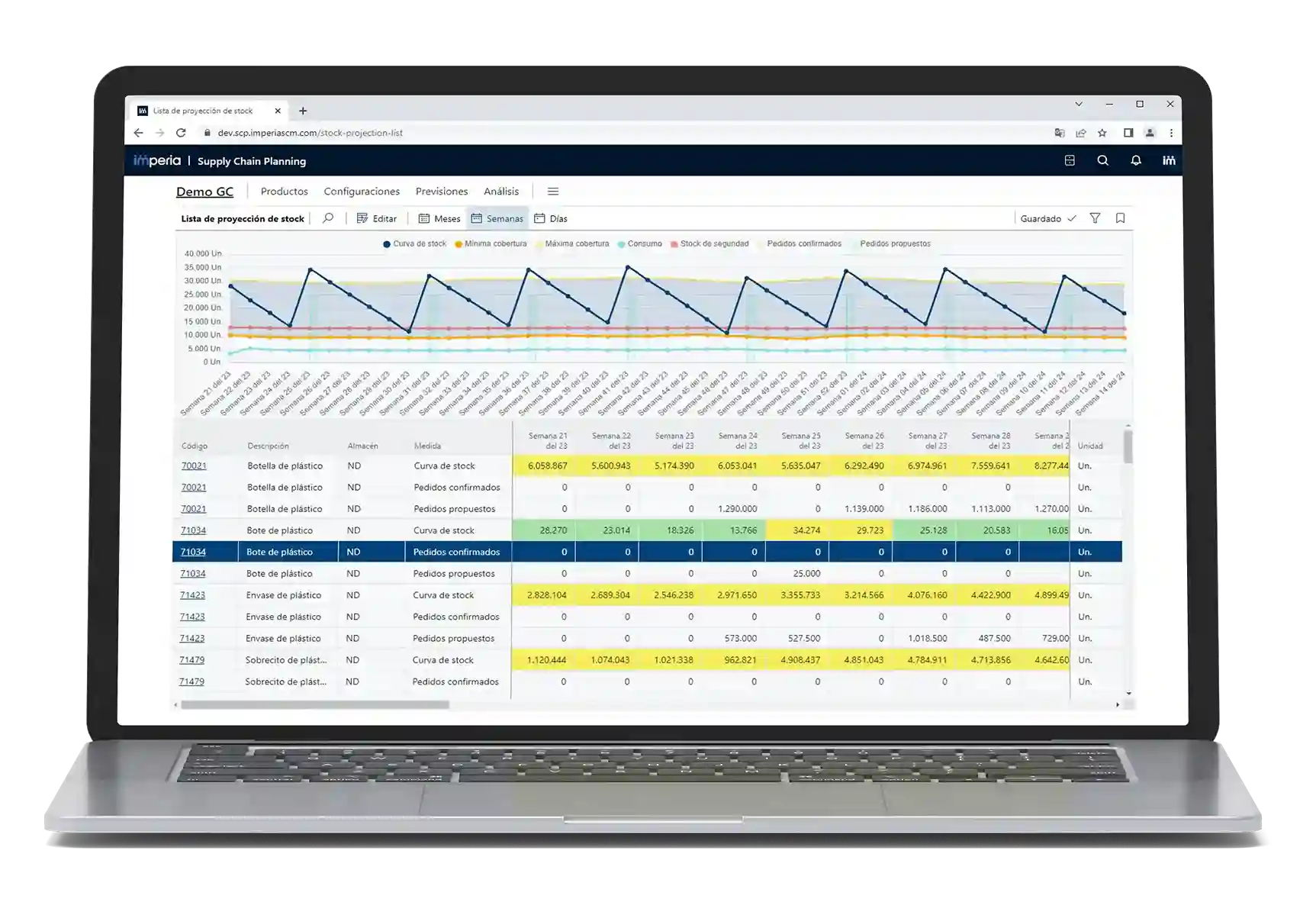

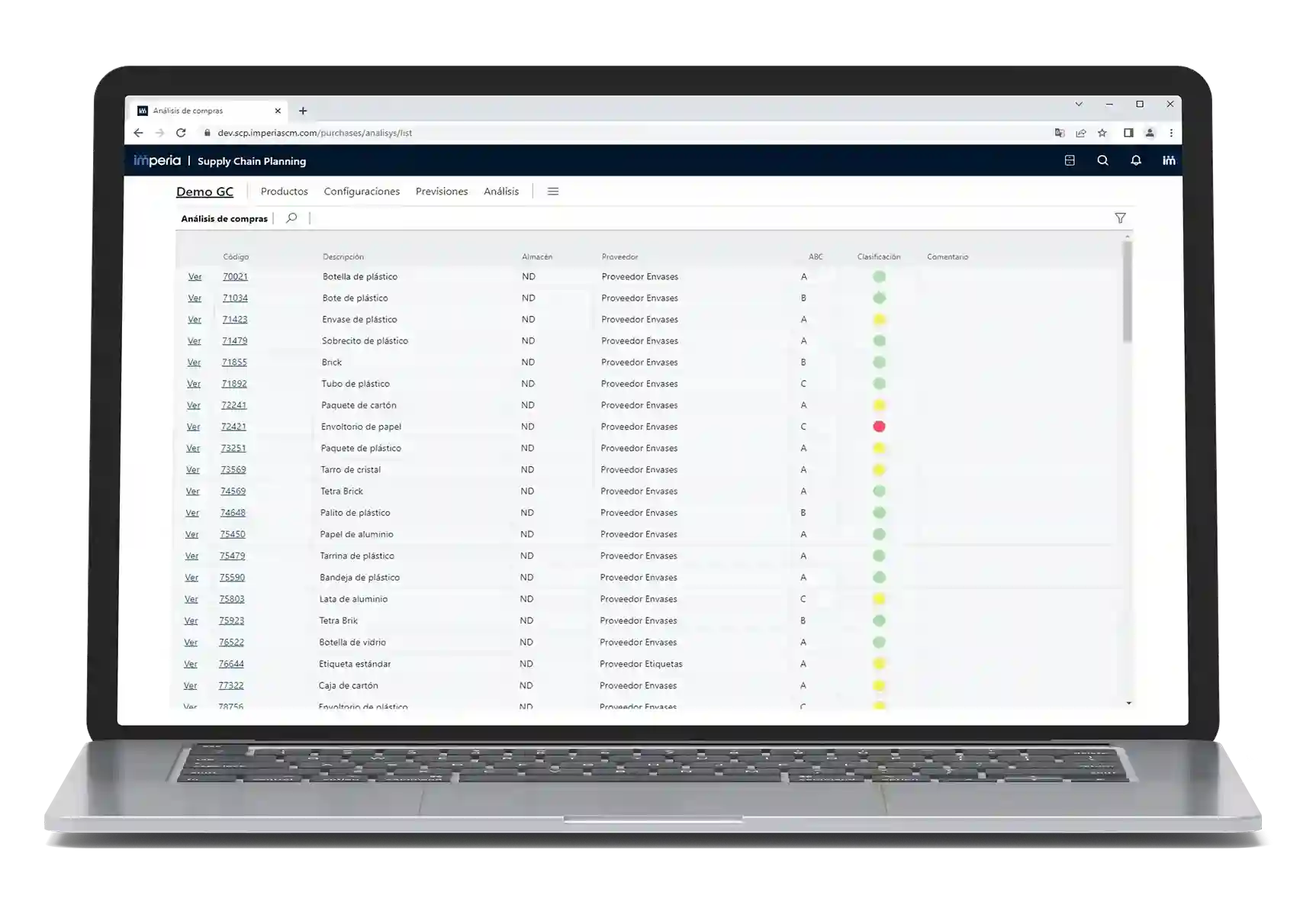

- Compras

Optimiza tus procesos unificando planificación de la demanda, compras y producción en un sistema integrado, proporcionando una solución completa para la gestión de tu cadena de suministro.

Planifica tu ciclo de ventas y operaciones en un calendario integrado con sistema de notificaciones en tiempo real. Mantendrás un seguimiento constante de los hitos críticos de tu ciclo de S&OP.

Gestiona con visión end-to-end todo tu proceso de planificación de demanda. Lanza tus previsiones de ventas con modelos avanzados de cálculo y analiza sus desviaciones.

Elabora tu plan de producción con precisión y basándote en tus necesidades reales, optimizando tus recursos y alineando tus capacidades de fabricación.

Planifica tus compras de forma ágil y sencilla con nuestra solución, que te permite automatizar y optimizar todos tus pedidos de compra a proveedor.

Reducción de inventarios

Identifica y conoce cuánto ahorras optimizando tu cadena de suministro.

Incrementa la productividad

Ahorra tiempo en tus procesos y toma mejores decisiones.

Mejora el servicio al cliente

Mejora tus previsiones y aumenta la satisfacción de tus clientes.

Empresas referentes que planifican sus procesos con Supply Chain Planning

Solución ágil y flexible, con alto valor para la planificación de cualquier compañía. Te da visibilidad a corto, medio y largo plazo para eficienciar tus procesos, muy recomendable y equipo comprometido con el servicio al cliente.

Cuento con más de 20 años de experiencia internacional en distintas áreas de la supply chain y recomendaría por completo el software de Imperia SCM. Su enfoque hacia la planificación operativa, permite a la empresa obtener numerosos beneficios desde el primer momento una vez se comienza a utilizar la solución. Las cuotas se aplican de forma mensual, por lo que el precio es asequible para todo tipo de compañías. Muy recomendable!

La solución que ofrece Imperia es una de las más completas que he encontrado, tanto por su funcionalidad como por la dedicación y acompañamiento 100% de su equipo de operaciones para garantizar el éxito del proyecto. El trato es totalmente personalizado y la atención al cliente es impecable.

Con mi experiencia como director de operaciones en el sector de la alimentación en el tejido industrial PyMe, considero que el software que ofrece Imperia es perfecto para mejorar la eficiencia de la cadena de suministro de cualquier compañía en el sector con una visión end-to-end y partiendo del origen, la planificación de demanda. Trabajo impecable por todo su equipo de operaciones.

Trabajamos desde hace años con ellos y estamos muy satisfechos con los resultados. La herramienta nos ha ayudado a ordenar y poner procesos en nuestras operaciones de previsión de demanda y aprovisionamiento. Una herramienta amigable, práctica y de alto valor añadido.

Equipo comprometido con la excelencia y servicio, la solución que ofrece Imperia es única en el mercado, capaz de cubrir el proceso de planificación completo, desde la demanda hasta la planificación de producción y aprovisionamiento. Además de permitir soportarlo desde un enfoque 100% orientado al usuario, gracias a su integración con Excel y agilidad en la operativa de sus procesos.

Solución ágil y flexible, con alto valor para la planificación de cualquier compañía. Te da visibilidad a corto, medio y largo plazo para eficienciar tus procesos, muy recomendable y equipo comprometido con el servicio al cliente.

Cuento con más de 20 años de experiencia internacional en distintas áreas de la supply chain y recomendaría por completo el software de Imperia SCM. Su enfoque hacia la planificación operativa, permite a la empresa obtener numerosos beneficios desde el primer momento una vez se comienza a utilizar la solución. Las cuotas se aplican de forma mensual, por lo que el precio es asequible para todo tipo de compañías. Muy recomendable!