What Is Aggregate Planning and Why Is It Key to Production Management?

Table of contents

In any efficient supply chain, decision-making can’t be limited to what’s urgent or immediate. Businesses operating with a mid-term outlook need a tool that allows them to balance projected demand with available resources, without falling back on reactive adjustments. This is where aggregate planning comes in.

This approach provides an operational view across a 3- to 18-month horizon, helping to align demand, production, procurement and logistics. In this article, we’ll explain what aggregate planning involves, its objectives and benefits, and how it can support better tactical decision-making. Let’s get started.

What Is Aggregate Planning?

Aggregate planning is a mid-term planning methodology designed to determine production quantities, inventory levels and capacity needs. Unlike short-term planning, it doesn’t focus on individual SKUs but works with product families, resource groups or overall capacity.

Its main role is to translate the company’s strategic plan into realistic operational needs, serving as a bridge between demand forecasts and detailed execution via the master production schedule (MPS).

Key Features of Aggregate Planning

- Planning horizon of 3 to 18 months.

- Focus on aggregated units or product families.

- Enables tactical decisions without needing SKU-level detail.

- Integrated within the Sales & Operations Planning (S&OP) process.

Objectives of Aggregate Planning

The key goals of aggregate planning include balancing supply and demand, optimising resource use, reducing overall costs and aligning cross-departmental decisions.

Balancing Supply and Demand

The primary aim is to align available capacity with forecasted demand, defining when to ramp up production, outsource, or adjust shifts to avoid stockouts or excessive build-up.

Optimising Resource Use

Aggregate planning helps prevent under- or over-utilisation of critical resources like machinery, workforce or suppliers.

Reducing Total Costs

By evaluating options like overtime, outsourcing or stockpiling, the organisation can choose the most cost-effective approach.

Aligning Cross-Functional Decisions

It provides a shared view that connects commercial, operations, procurement and finance teams, supporting joint decision-making.

Demand and Capacity Variables in Aggregate Planning

Aggregate planning focuses on representative variables that simplify the model without compromising decision accuracy. These variables support operational decision-making without needing SKU-level detail, focusing instead on trends, overall capacity and shared constraints.

Demand-Side Variables

- Aggregate forecasts by product family: Enables planning across groups of similar SKUs, for example, grouping ten refrigerated dairy SKUs under one demand profile.

- Seasonality by channel or customer type: Helps account for sales peaks (e.g. summer, Christmas, promotional windows).

- Expected events (campaigns, regulatory changes): Incorporates known disruptions into the forecast for an entire product family.

Capacity-Side Variables

- Shift availability and working calendars: Takes into account holidays, maintenance and leave to avoid overestimating available time.

- Equivalent production capacity: Standardises planning units to enable cross-family comparisons.

- Outsourcing capacity: Offers flexibility by including third-party manufacturing options.

- Logistics and storage resources: Ensures that production plans also factor in warehouse space and transport capacity.

Common Methods and Strategies in Aggregate Planning

Effective aggregate planning requires both solid forecasting and a clear resource strategy.

Planning Strategies

- Chase demand: Matches production to monthly demand. Minimises stock but requires flexible resources.

- Level production: Maintains a steady production pace. Reduces operational stress but can lead to higher storage costs.

- Hybrid approach: Balances the two, with defined capacity thresholds and some flexibility built in.

Quantitative Techniques

- Scenario-based cost models: Compare total costs across different planning strategies (overtime, inventory, outsourcing, etc.).

- Heuristic balancing methods: Use empirical rules to distribute demand across resources.

- Linear programming: Optimises multiple variables under real constraints, ideal for complex environments.

These methods can be applied manually or embedded within SCM software.

The Role of Forecasting in Aggregate Planning

Forecasts are critical inputs, even at family or group level. Poor forecasting leads to:

- Overproduction.

- Excess inventory.

- Capacity shortfalls.

It’s essential that forecasts are aligned with the aggregate planning structure and updated regularly to reflect market changes.

Applying Aggregate Planning

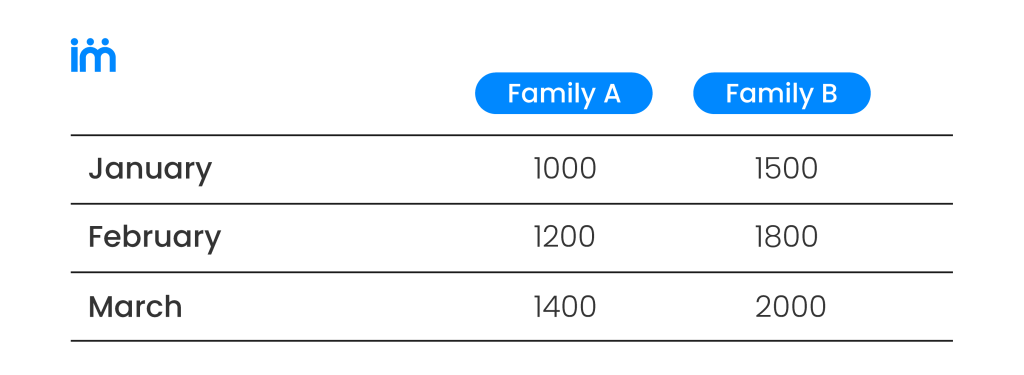

Imagine a company with two product families (A and B). Demand forecasts for the quarter are:

With a static monthly production capacity of 2,000 units, the company must decide whether to:

- Outsource part of the production.

- Build inventory in January for use in March.

- Add shifts or apply overtime.

The most cost-effective plan depends on scenario evaluation, automated by supply chain planning software.

Benefits of Well-Executed Aggregate Planning

Good aggregate planning improves internal coordination and boosts both operational and financial efficiency. Key benefits include:

- Lower overall costs by avoiding reactive decisions.

- Better use of capacity, no overloads or idle time.

- A more reliable master plan based on realistic assumptions.

- Improved service levels, fewer stockouts and less excess.

- Organisational alignment a solid foundation for the S&OP process.

Aggregate Planning: A Strategic Decision with Operational Impact

Aggregate planning is essential for any manufacturing or FMCG company that wants data-driven decision-making aligned with strategy. It enables anticipation, resource balancing and efficient operations without sacrificing agility.

With tools like Imperia’s SCP, the process becomes transparent, collaborative and adaptive. Because great planning doesn’t mean getting every detail right means enabling better decisions when conditions change.

Ready to implement aggregate planning in your organisation? Book a free consultation and discover how we can turn planning into a competitive advantage.

Subscribe to our newsletter and transform your management!

Receive updates and valuable resources that will help you optimise your purchasing and procurement process.