Automation in SCM: What Processes to Prioritise in 2025 and Why

In 2025, automation in SCM is no longer a question of the future, but of the present. Companies looking to scale their efficiency, reduce errors, and adapt to the market with agility must consider which processes to automate and in what order. It’s not about digitising everything without a clear plan but knowing where to start to achieve the greatest operational and organisational return. This post will help you make informed decisions, understanding which factors to consider, which processes have the most impact, and the role SCM software plays in this journey.

Automation in SCM is Not about Digitising Everything, It’s About Making the Right Decisions

Automation in SCM has shifted from being a competitive advantage to becoming a necessity for survival. However, many companies make the mistake of thinking automation simply means adding technology tools or digitising forms. Intelligent automation involves understanding which processes are most susceptible to improvement, which add the most value to the business, and which should still rely on human judgement or collaborative validations.

Automating for the sake of it generates rigid systems, disconnected processes, and, in many cases, more complexity than benefits. For this reason, 2025 must be the year when companies in the industrial, logistics, and production sectors start deciding which processes to automate first, with what goals, and with clear impact evaluation criteria.

What Factors to Consider in SCM Automation?

Not all processes are equally suited or profitable to automate. Before implementing any technological solution, it is essential to assess the factors that determine whether a process is ready and justified for automation.

It’s not just about having available technology, but ensuring the process has impact, maturity, and a solid data and organisational structure. Evaluating these factors critically is what distinguishes successful automation from ineffective investment. Let’s take a look at the key pillars that should guide this decision.

Operational and Strategic Impact

Not all processes have the same weight in the supply chain. Some directly affect customer service, logistics costs, or operating margins, while others have a marginal impact. Automating a process should answer the question: How much does this process affect the overall performance of my supply chain?

For example, automating demand forecasting has a domino effect on inventory, purchasing, and production. However, digitalising internal label approvals may be useful but doesn’t have such a direct impact on profitability or competitiveness. Identifying which processes act as «leverage points» is key to prioritising effectively.

Digital Maturity of the Process

Before automating, it’s important to assess how mature the process is. A mature process has defined steps, clear responsibilities, associated KPIs, and a stable workflow. If it is still in a manual and reactive management phase, it’s better to standardise it first.

Automating an immature process can lead to errors. In contrast, when there is a clear and repeatable structure, automation can yield significant improvements in time, quality, and cost. Therefore, automation should be preceded by a review of the process.

Data Visibility and Organisational Structure

A process cannot be automated without accessible, structured, and up-to-date data. If the necessary data is scattered across spreadsheets, emails, or unintegrated systems, automation will be incomplete or unreliable. Data quality is a fundamental requirement.

This also requires having an organisational structure that supports automation. If no one is responsible for the process or there are grey areas between departments, the technological implementation may fail due to lack of leadership. Automation requires data and clear leadership.

SCM Automation in 2025: 7 Processes You Must Automate

In today’s increasingly competitive environment, where speed, planning accuracy, and operational efficiency are key differentiators, not all processes deserve the same level of attention when it comes to automation. Some generate immediate and scalable returns when digitised and integrated into an SCM system.

Here are the 7 supply chain processes you must automate in 2025, which should be a focus for any organisation looking to optimise operations, reduce costs, and increase production capacity.

1. Demand Forecasting and Planning

Demand forecasting is the first link in the supply chain. Automating this process using advanced statistical models, machine learning, and collaborative forecasting reduces errors, anticipates seasonal or promotional variations, and adapts planning more accurately.

Furthermore, automating the consolidation of sales, marketing, and operations data eliminates information silos and speeds up decision-making. A digital solution enables configuring different forecasting horizons, managing hierarchies, and applying algorithms tailored to the real behaviour of each reference.

2. Inventory Management and Safety Stock

Automating the calculation of safety stock and optimal inventory levels based on turnover, lead time, and the criticality of each item is key to reducing logistics costs and avoiding stockouts. When this process is automated, it helps maintain service levels without unnecessarily inflating working capital.

Using supply chain optimisation software allows parameters to be adjusted based on real behaviour and enables automatic replenishment rules, ABC classification, or coverage adjustments by channel or customer.

3. Production Scheduling and Sequencing

One of the most complex processes in the supply chain is production sequencing, especially in environments with finite capacity, costly setups, or high customisation. Automating this task allows for feasible plans, reduces bottlenecks, and better utilises available capacity.

A production sequencing tool integrates line constraints, changeover times, priority rules, and logistical conditions to generate an optimal production order and timing proposal.

4. Automatic Replenishment and Purchasing

Automating order suggestions based on real consumption, supplier conditions, and target stock levels avoids both overstock and supply shortages. It’s one of the simplest processes to automate and has the most direct impact on operational efficiency.

Procurement software generates automatic orders, validates contractual conditions, and prioritises suppliers based on lead time, price, or service quality.

5. Control Tower and Real-Time Visibility

A SCM control tower allows for monitoring the entire supply chain in real time, detecting issues, and triggering automatic alerts for deviations in critical KPIs. Automating this visualisation improves response capacity and enables corrective decisions to be made swiftly.

The control tower centralises demand, inventory, orders, capacity, and transportation data, creating a visual and operational environment for proactive supply chain network supervision.

6. Transport and Route Optimisation

Planning distribution routes, consolidating orders, or assigning transports based on capacity and cost are processes that greatly benefit from automation through algorithmic logic. The impact on cost per kilometre, emissions, and punctuality is direct.

Transport optimisation solutions consider load restrictions, time windows, delivery zones, and associated costs to automatically propose optimal routes.

Product or Customer Segmentation (MEIO, ABC, XYZ)

Automating the classification of products based on consumption behaviour, strategic value, or logistical criticality allows for differentiated stock, service, and replenishment policies. This maximises operational efficiency and resource focus.

Digital solutions enable dynamic segmentation using MEIO, ABC/XYZ methodologies and customisable conditional rules by business, channel, or location.

Which Processes Are Better Not to Automate Yet?

Although automation offers clear benefits in efficiency, agility, and error reduction, not all processes are ready for automation. There are situations where forcing automation can create more problems than improvements, compromise decision-making quality, or amplify existing inefficiencies.

In this section, we identify three common scenarios where it’s advisable to be cautious and evaluate the process maturity, organisational support, and data quality before introducing automation.

Tasks Dependent on Expert Judgement

Some tasks require a high degree of human judgement, such as negotiating commercial conditions, making strategic decisions in uncertain environments, or handling conflicts between departments. Automating these processes can weaken the outcome or create unnecessary rigidity.

Technology should complement expert knowledge, not replace it. In these cases, it’s better to opt for tools that support analysis and scenario visualisation without removing human intervention.

Processes Without Structured Data

If the data feeding a process is not normalised, updated, or consolidated in a single platform, any automation will be built on an unstable foundation. Before automating, it’s essential to work on data quality, integrity, and reliability.

A good practice is to establish data quality KPIs and automatic validation processes before launching critical automation.

Grey Areas Between Departments Without Clear Ownership

When a process is distributed across multiple departments with no clear ownership, bottlenecks, duplications, or disconnections are likely to arise. Automating without first resolving organisational ambiguity usually creates more problems than solutions.

In these cases, it’s best to clarify roles, responsibilities, and workflows before considering the technical automation of the process.

How SCM Software Enables Automation

Supply chain process automation doesn’t just depend on the company’s willingness, but on having the right tool to do it progressively, controlled, and aligned with real operational maturity. SCM software should offer the flexibility to adapt automation to each company’s priorities and capabilities.

Let’s explore how an SCM solution enables modular, specialised automation that integrates seamlessly with the existing technology ecosystem.

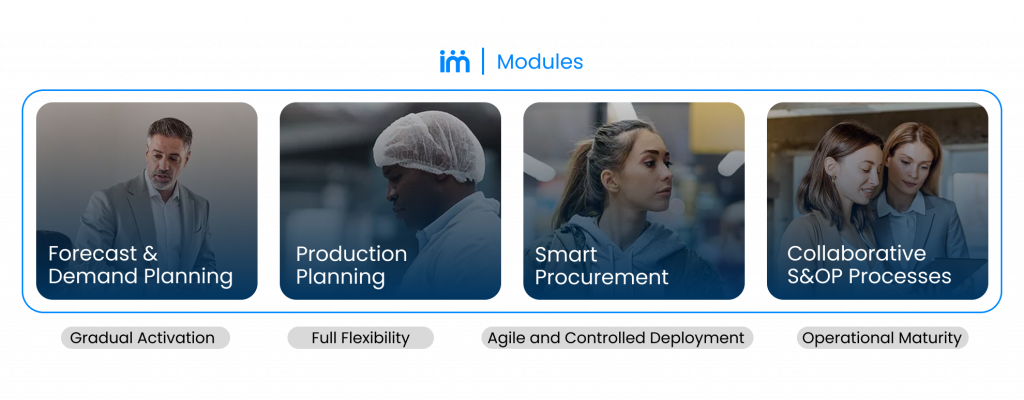

Modularity, Scalability, and Layered Automation

Modern SCM software doesn’t impose total automation from the outset; instead, it allows you to modularise the process: starting with the highest-impact areas, measuring results, and scaling progressively.

It must be capable of configuring automation levels by process, area, or operational phase, matching the client’s real maturity without forcing the pace of transformation.

Specialised Plugins by Process and Maturity

Each organisation has different needs. That’s why having specific functionalities for forecasting, inventory, production, or purchasing, which can be activated depending on where the company stands, is an advantage.

This avoids overloading the system with unused features and allows the team to focus on automating what truly adds value at that moment.

Integration with ERP, CRM, and Plant Systems

Automation only works if it’s connected to the systems that are already part of the company’s ecosystem. It’s important to have a tool that integrates with ERPs, plant systems (MES), CRMs, supplier portals, and other platforms, ensuring that automation creates a unified operational network, not silos.

SCM Automation: Do It with Intelligence, Not in a Hurry

Automation is a decision that can transform your supply chain or become a source of rigidity if applied without criteria. In 2025, automating is not about implementing technology for the sake of it, but identifying which processes have the greatest impact, which are ready to be scaled, and which require solid data and organisation first.

At Imperia, we help our clients automate intelligently: selecting the right processes, measuring the return of each step, and offering modular tools tailored to each company’s maturity level.

If you’d like to know how we can assist with your SCM automation, don’t hesitate to request a free consultation with our experts. We’d be happy to help!

Subscribe to our newsletter and transform your management!

Receive updates and valuable resources that will help you optimise your purchasing and procurement process.