Automation in SCM: What to Prioritize in 2025, and Why It Matters

In 2025, automation in SCM is no longer a futuristic concept, it’s a strategic priority. Companies aiming to scale efficiency, cut errors, and stay agile in a shifting market must decide which processes to automate and in what order. It’s not about digitizing everything overnight but about identifying the right starting points to drive real operational and organizational impact.

This article will help you make informed decisions: what to consider, which processes deliver the highest return, and how SCM software enables scalable, effective automation.

Automation in SCM Is About Smarter Decisions, Not Just More Technology

Automation has evolved from a competitive edge to a business imperative. But many companies still equate it with simply adding new tools or digitizing forms. Real automation means identifying which processes deliver the most value, which are ready to scale, and which still depend on human insight.

When automation is poorly planned, it creates rigidity, fragmented systems, and more complexity than benefit. That’s why 2025 must be the year companies in manufacturing, logistics, and operations start making deliberate, impact-based automation decisions, with clear objectives and measurable results.

What to Consider Before Automating a Supply Chain Process

Not every process is equally suited, or ready, for automation. Before adopting any new solution, companies need to assess whether a process meets the criteria for successful automation.

The question isn’t just “can we automate this?” but “should we?” Let’s break down the key factors that determine readiness and impact.

Strategic and Operational Impact

Start by evaluating how much a process influences your overall performance. Does it affect customer experience? Margins? Fulfillment reliability? If the answer is yes, it’s a strong candidate for automation.

For instance, automating demand forecasting has a cascading effect on inventory, procurement, and production. In contrast, digitizing internal label reviews may be helpful, but won’t move the needle on performance or profit.

Process Maturity

A process needs structure before it can be automated. If workflows are undefined, ownership unclear, and KPIs nonexistent, automation will only amplify the chaos. But if the process is stable and repeatable, automation can drive dramatic gains in speed, accuracy, and efficiency.

Standardize first, then automate.

Data Availability and Organizational Alignment

No automation effort succeeds without clean, structured, and accessible data. If data is scattered across spreadsheets, emails, or disconnected platforms, the result will be unreliable and incomplete.

Just as critical: ownership. If no one owns the process or if it’s stuck in a cross-functional gray area, automation will stall. Data and leadership are the foundations.

7 Supply Chain Processes You Should Automate in 2025

In today’s high-pressure environment, not all automation efforts deliver equal returns. Some processes offer fast, scalable benefits when digitized and embedded in a smart SCM platform.

Here are the top 7 processes to prioritize in 2025:

1. Demand Forecasting and Planning

Forecasting demand is where supply chains begin, and automation here pays off fast. Advanced algorithms, machine learning, and collaborative input reduce forecast errors and improve agility around seasonal trends or promotions.

A digital solution centralizes sales, marketing, and operations data; enables multi-tiered planning; and applies models that reflect real demand behavior.

2. Inventory Management and Safety Stock Optimization

Automating stock calculations based on turnover, lead time, and criticality keeps working capital in check while maintaining service levels. You avoid overstocking and reduce the risk of running out of high-priority items.

SCM tools let you define replenishment logic, segment products (ABC, XYZ), and apply differentiated policies by channel or customer.

3. Production Scheduling and Sequencing

Production, especially in capacity-constrained or high-mix environments, is one of the most complex planning challenges. Automation enables executable plans that minimize downtime and improve asset utilization.

An intelligent scheduler incorporates constraints, changeovers, routing logic, and delivery priorities to generate an optimal sequence with minimal manual effort.

4. Automated Replenishment and Procurement

Automating purchase orders based on actual consumption, supplier conditions, and target inventory levels eliminates guesswork. It’s one of the most impactful and accessible automation opportunities.

Procurement software can generate and validate orders, enforce contract terms, and prioritize suppliers by lead time, price, or performance.

5. Control Tower and Real-Time Monitoring

A supply chain control tower offers end-to-end visibility, detects disruptions as they happen, and triggers automated alerts for deviations. This boosts response speed and improves decision-making under pressure.

With a centralized view of demand, inventory, capacity, and transportation, teams can monitor the full network and respond proactively.

6. Transportation and Route Optimization

Optimizing deliveries, consolidation, route planning, fleet assignment, is an ideal area for automation. Algorithms reduce miles, emissions, and delays, while boosting on-time delivery and lowering cost-per-shipment.

Advanced tools evaluate load constraints, time windows, customer zones, and transportation costs to generate optimized routes automatically.

7. Segmentation (MEIO, ABC, XYZ)

Automating product and customer segmentation helps tailor replenishment, inventory, and service policies. It drives efficiency by aligning operations with real business priorities.

Digital solutions apply MEIO logic or ABC/XYZ rules dynamically, based on behavior, margins, and logistics profiles, automatically updating policies as conditions change.

What Not to Automate, At Least Not Yet

While automation unlocks speed and consistency, not every process is ready. In some cases, pushing for automation too early can reduce decision quality or create rigidity. Watch for these warning signs:

Expert-Driven Tasks

Strategic decisions, complex negotiations, or conflict resolution between teams often require human judgment. In these cases, automation should enhance, not replace, expertise.

Look for tools that support analysis and visualization, without removing human input.

Unstructured or Poor-Quality Data

If your data is fragmented, outdated, or poorly maintained, automation will only amplify the flaws. Focus on data cleansing and quality KPIs before automating anything mission critical.

Undefined Ownership Across Teams

If a process lacks clear owners, or spans multiple departments with unclear accountability, automation can lead to confusion. First, clarify roles and handoffs. Then automate.

How SCM Software Powers Smart Automation

Automation isn’t just about technology, it’s about having the right tools to do it progressively, strategically, and at scale. A modern SCM platform should be flexible enough to match your company’s maturity and priorities.

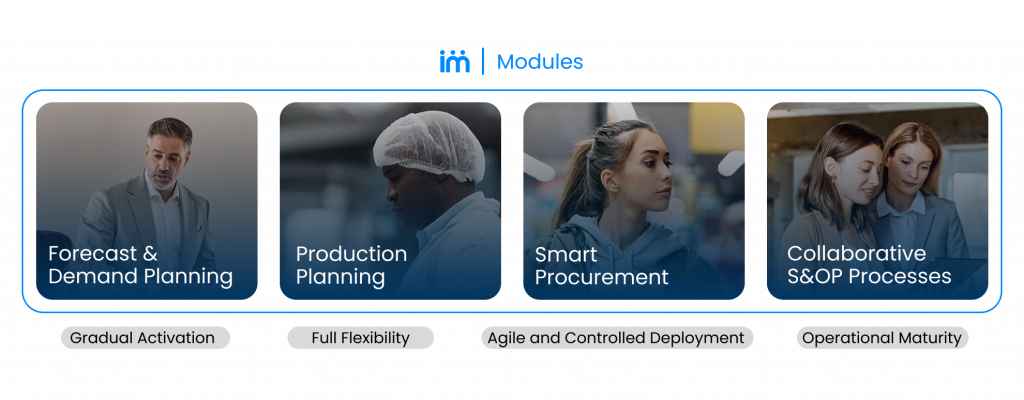

Modular and Scalable Automation

The best tools allow for phased adoption. Start small, track results, and scale gradually. You can automate by function, business unit, or workflow layer, without overhauling everything at once.

Specialized Plugins Based on Your Needs

No two companies are alike. SCM software should offer process-specific plugins, forecasting, inventory, scheduling, etc., that activate only when needed. That keeps systems lean and focused.

Seamless Integration Across Systems

Automation must connect to your broader tech ecosystem. Look for platforms that integrate with ERP, MES, CRM, supplier portals, and creating a unified, real-time data flow across the supply chain.

SCM Automation in 2025: Be Strategic, Not Reactive

Automation isn’t about going digital for the sake of it. It’s about making strategic decisions based on readiness, impact, and long-term value.

In 2025, the smartest companies won’t automate everything, but they will automate the right things, at the right time, with the right tools.

At Imperia, we help businesses automate intelligently prioritizing high-impact processes, measuring ROI, and offering flexible, modular tools tailored to your real-world operations.

Want to learn more about SCM automation? Schedule a free consultation with one of our experts. We’ll help you plan your next step with confidence.

Subscribe to our newsletter and transform your management!

Receive updates and valuable resources that will help you optimize your purchasing and procurement process.