In the world of supply chain management, punctuality and accuracy are two fundamental concepts to achieve efficiency and customer satisfaction. In today's article, we will delve into a KPI that helps us measure the effectiveness of a company's logistics: OTIF (On Time In Full). We will look at what it is, why it is important, how to calculate it, and what strategies we can implement to improve it. Get ready to discover how this metric can turn your supply chain into a powerhouse of efficiency and operational excellence.

What is OTIF?

OTIF, On Time In Full, is a metric that focuses on the timeliness and completeness of deliveries. In short, OTIF refers to a company's ability to deliver its products to customers at the agreed time and in the specified quantity and quality. It is a key indicator of the efficiency and effectiveness of the entire supply chain, as it encompasses inventory and production management as well as logistics and distribution.

This means that it is not only about meeting the promised delivery deadlines to the customer but also ensuring that the products are available in the right quantity and without defects or damages. Therefore, OTIF represents a company's commitment to operational excellence and customer satisfaction, while also driving efficiency and profitability throughout the supply chain.

Why is OTIF important in the supply chain?

OTIF is one of the key indicators for supply chain management because it directly affects customer satisfaction, operational efficiency, and the company's profitability. The timeliness and completeness of deliveries are crucial elements for the success of any logistics operation, and OTIF is a tool that allows us to evaluate and improve performance in these aspects.

First, OTIF is important because it is closely related to customer satisfaction. Delivering products on time and in the correct quantity and quality is essential to meet customer expectations and maintain their trust in the brand. A high OTIF compliance rate translates into higher customer satisfaction and, in turn, greater customer loyalty and retention in the long term.

On the other hand, OTIF plays a crucial role in the operational efficiency of the supply chain. Meeting delivery deadlines and avoiding inventory shortages or excesses helps minimize operational costs and optimize available resources. An efficient supply chain allows for reduced lead times, improved asset utilization, and increased productivity.

Additionally, OTIF is important from a financial perspective. A high OTIF compliance rate translates into a reduction in costs related to returns, delays, and penalties for contract breaches. It also improves demand predictability and facilitates more accurate planning, contributing to stronger financial management and greater profitability.

Thus, OTIF is an indicator that impacts multiple aspects of the supply chain, from customer satisfaction to operational efficiency and financial profitability. Monitoring and improving it are essential to ensure the long-term success of any company in a competitive and constantly changing environment.

How to calculate OTIF

Now that we know what OTIF is and its importance within the supply chain, let's see how we can calculate it. To do this, we need to define the criteria that will determine whether a delivery is considered on time and complete and gather information on all deliveries made during the period for which we want to calculate OTIF.

To determine how we will measure if a delivery has been made on time and in full, we can use different criteria. For example, if delivery dates were met, if the quantities of products per order were achieved, or if the products met the quality specifications agreed with the customer.

Once the criteria are established, we analyze the orders delivered during the period and assess whether they met the set parameters. With this data, we can calculate our OTIF.

To calculate it, we divide the number of deliveries made on time and in full by the total number of deliveries made, and multiply the result by 100 to get the percentage.

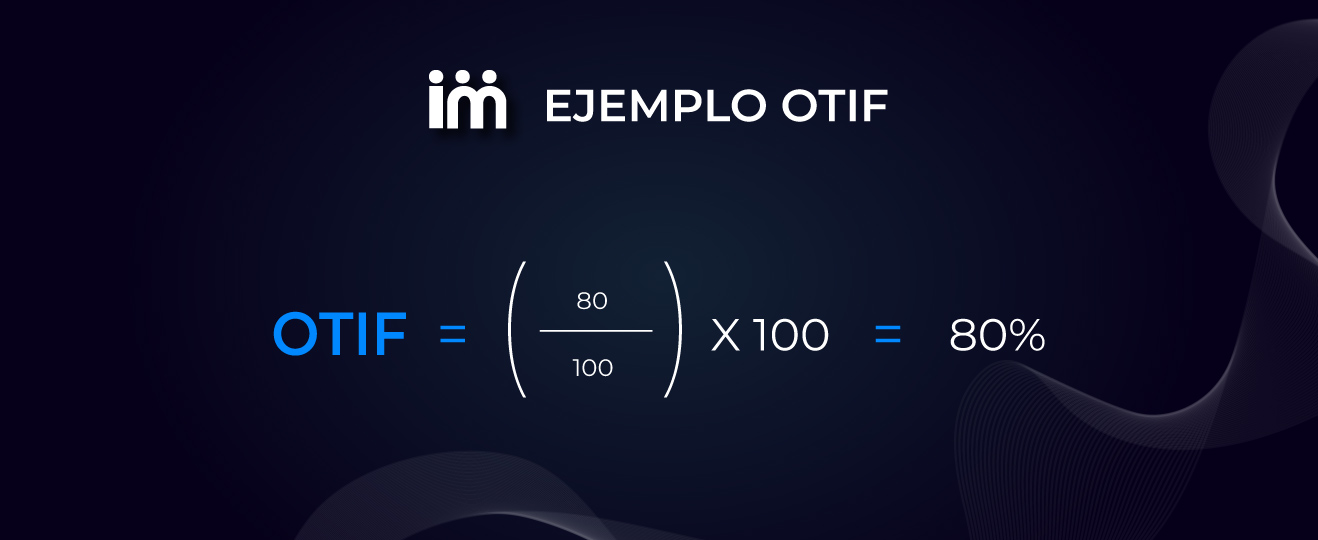

Example of OTIF calculation

To see more clearly how OTIF is calculated, let's give a practical example. Imagine a company that sells shoes made from recycled materials. In the last month, they delivered a total of 100 orders. Of these orders, 80 were delivered within the agreed time frame and with the expected quantity and quality. On the other hand, 20 orders had some type of incident, such as a delivery delay or defective shoes.

To calculate OTIF, we divide 80 by 100 and multiply the result by 100. Therefore, the calculation would be:

Therefore, the company had an OTIF of 80% during the last month.

Factors affecting OTIF compliance

OTIF compliance is influenced by a variety of factors that can affect a company's ability to deliver products on time and in full. These factors can come from different areas of the supply chain, and it is important to identify and address them appropriately to improve performance.

Logistical and operational challenges

Logistical and operational challenges can present significant obstacles to OTIF compliance. This includes issues such as transportation delays, supplier problems, order processing errors, and insufficient capacity in warehouses and distribution centers. To address these challenges, companies should implement efficient logistics practices, optimize transportation routes, improve production planning and maintain effective communication with all supply chain actors.

Inventory planning and management

Ineffective inventory planning and management can lead to OTIF compliance issues. Inadequate inventory levels can result in product shortages or surpluses, affecting the ability to meet delivery deadlines and quantities requested by customers. To improve OTIF, companies should implement robust demand planning and inventory management systems that allow them to accurately forecast inventory needs and maintain optimal levels at all times.

Tools to improve OTIF

There are several tools and technologies available that can help improve OTIF compliance. These include warehouse management systems, demand planning software, real-time tracking and monitoring tools, and data analysis solutions. By leveraging these tools, companies can optimize their processes, identify areas for improvement, and make informed decisions to ensure optimal OTIF compliance.

3 Strategies to improve OTIF compliance

Improving OTIF compliance is crucial to ensure customer satisfaction and operational efficiency in the supply chain. To achieve this, companies can implement a series of strategies and practices that address different aspects of their operations. Below, we present three possible strategies to achieve OTIF compliance:

Optimization of routes and transportation

Route and transportation optimization plays a key role in OTIF compliance. Using fleet management technology and routing software can help companies plan the most efficient routes, minimizing travel times and reducing operation costs. Additionally, effective coordination with carriers and real-time monitoring of deliveries allows for a quick response to any unforeseen events, ensuring timely deliveries.

Proactive inventory management

Proactive inventory management is essential to improve OTIF compliance. This involves maintaining optimal inventory levels at all times, anticipating demand, and optimizing stock levels based on consumption forecasts. The use of accurate forecasting and inventory management software allows companies to minimize stock shortages and excesses, ensuring product availability when customers need it.

Improving supply chain planning and visibility

Improving supply chain planning and visibility is essential to optimize OTIF compliance. Companies can use demand planning tools and programs like our Supply Chain Planning software to coordinate production, distribution, and product delivery more effectively. By having a complete view of all aspects of the supply chain, companies can identify potential bottlenecks and take preventive measures to avoid interruptions in the product flow.

Controlling OTIF for an efficient supply chain

In conclusion, controlling OTIF is essential to ensure an efficient and competitive supply chain. By continuously monitoring and improving compliance with this indicator, companies can increase customer satisfaction, optimize their operations, and improve profitability. Implementing strategies, such as route optimization or improving supply chain planning, are essential to improve OTIF compliance.

Additionally, it is crucial to continuously monitor the factors affecting this KPI and take quick corrective actions when necessary. With a focus on controlling this indicator, companies can better position themselves to face market challenges and achieve long-term success in an increasingly competitive business environment.

At Imperia, we have extensive experience optimizing our clients' supply chains, increasing their efficiency and productivity. Thanks to our supply chain software, we are able to improve companies' competitiveness. If you want to learn more about the potential of our tool, do not hesitate to request a free demo with our experts. We look forward to seeing you!

Enter your email and download the content

In supply chain management, identifying key elements that require special attention can make the difference between success and failure.

Imperia_thumbnail.jpg)