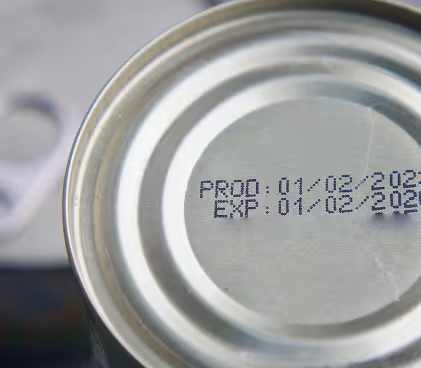

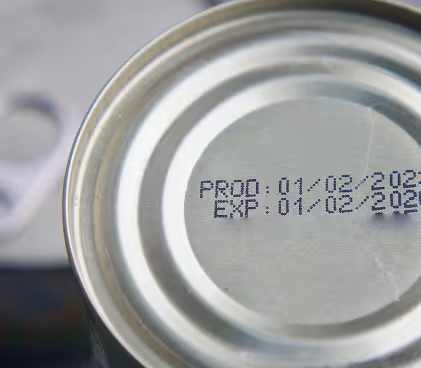

Expiration and obsolescence of perishable inventory

Perishable stock expires and generates losses.

Implement batch control and expiration alerts to anticipate shrinkage and optimize inventory rotation.

150+ companies trust us

Demand is marked by seasonality, promotions and the growing diversification of formats. Connecting forecasting, purchasing and production allows you to adjust inventory, avoid breakages during consumption peaks and maintain efficiency throughout the supply chain.

The sale of soups and broths increases with cold weather, festivities or local events, generating sudden peaks in demand that are difficult to anticipate.

A linear forecast causes critical breakages or excess perishable stock, affecting the continuity of supply and profitability.

Reduced margin and negative perception due to lack of star products, compromising customer satisfaction and brand image.

Recognize weekly consumption patterns to adjust forecasts based on seasonality and recurring events.

Adjust forecast for demand peaks to improve accuracy and reduce losses or breakages.

Maintain availability without inflating inventory or generating waste, guaranteeing efficiency and sustainability.

Restaurant and hotel backorders not reflected in the forecast generate mismatches between real demand and planned production.

Production follows the theoretical plan, causing partial deliveries and affecting the perception of service.

The absence of integration between sales and planning prevents absorbing real demand peaks in time, causing breakages and urgent reprocessing.

Integrate confirmed sales in real time to align forecast, production and distribution with effective demand.

Decide whether to replan or discard demand according to priority and available capacity, optimizing resources.

Maintain OTIF and avoid incident escalation through continuous synchronization between sales, planning and operations.

Changes between flavors, containers or formats require CIP cleaning and adjustments, generating downtime and loss of efficiency.

Sequencing ignoring finite capacity causes unfeasible orders, operational imbalances and resource overload.

Delays, overtime and waste derived from inefficient sequencing that does not optimize changeover times or productive load.

A realistic Gantt chart respecting change times to ensure achievable and productive planning.

Block unviable sequences and visualize daily saturation to anticipate overloads and improve resource allocation.

Reduce micro-stops and free up productive hours, increasing production efficiency and stability.

Imported ingredients and packaging with high MOQs or full containers limit flexibility and increase the risk of overstocks.

Incomplete orders make freight more expensive; Overbuying ties up capital and reduces inventory turnover.

The absence of prior alerts or simulations prevents optimization of container loading and causes reactive decisions.

MOQ alerts and automatic coverage calculation to adjust purchase volumes to actual demand.

Optimal load simulation before order launch to maximize transportation efficiency and reduce logistics costs.

Alternation of suppliers if the main one fails to guarantee supply and avoid productive stops.

Perishable stock expires and generates losses.

Implement batch control and expiration alerts to anticipate shrinkage and optimize inventory rotation.

Blind forecast causes stockouts or excess stock.

Use flexible forecasting based on historical analogues and initial sales to adjust demand for new products.

Urgent transfers and overstock due to lack of planning.

Centralize multi-warehouse management with real-time visibility to plan transfers and balance stock between centers.

Key indicators that offer a clear vision of the strategic weight that this industry has in the current and future global economy.

Data obtained from Statista*

Connect demand, procurement, and production through a modular cloud platform, designed to adapt to the unique needs of every industry.

Integration with all ERPs

100% Cloud, ISO 27001 Certification

Customer reviews

Measurable results

Ecosystem tailored to your needs

Quick implementation

Start with our demand module, the tool that allows you to calculate how much you will sell.

Add the features that suit your business. Scale at your own pace and expand when you need to, with our plugins.

Once you've added the features you need, get your price with our calculator. And if you have any questions, we'll sort them out for you.

“Imperia gives you the functionalities you need and not those on the market, a solution that adapts and you pay for what you need.” Pau Font, Supply Chain Manager at NOEL Alimentaria

Implementing the software with Imperia is a quick and straightforward process, starting with the integration of the demand module, and can be complemented with 2 new phases. Incorporating the purchasing module and the production module.

A process with full support from our team, with personalised training and consultancy.

Increase the accuracy of your predictions, bringing the predicted demand closer to reality.

Minimizes inventory losses due to damage or expiration.

Optimize your plant's productive resources and increase its efficiency.

Total Price:

€850,00

Schedule a meeting with our Supply Chain experts and discover the features that will make your supply chain a complete success.

Data controller: Imperia SCM Consulting, Ltd.

Purpose of processing: Manage your demo request and share information about our services.

Legitimacy: Consent granted by submitting the request form.

Recipients: There is no provision for communication to third parties, unless legally required.

Rights: Access, rectify and delete your data, as well as other rights explained in the Privacy Policy.