Differences in rotation between physical and online channels

Omnichannel inventory is not managed synchronously.

Omnichannel planning connects physical and digital stock, guaranteeing availability and avoiding duplication.

150+ companies trust us

The demand for soups, broths and creams is highly seasonal and sensitive to promotions and consumption changes. Distributors must guarantee availability at all times without oversizing inventory or affecting profitability.

Consumption increases with the cold or during festive periods, generating breakages or excess product.

Global forecasts do not reflect behavior by area or type of customer.

The drop in sales after seasonal peaks causes overstock and loss of margin.

The predictive forecast incorporates external variables (temperature, calendar, promotions) to adjust coverage by store.

Granular planning adapts demand by store, format and segment, improving the accuracy of the forecast.

The algorithms recalculate coverage at the end of each campaign and recommend redistribution or automatic liquidations.

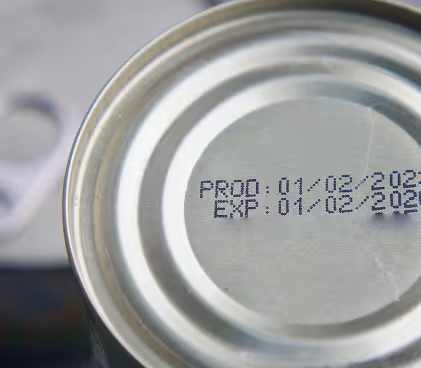

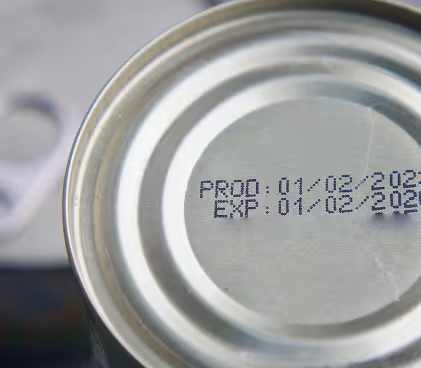

The packaged product has a limited useful life and requires continuous rotation.

Returns or registration errors make it difficult to track in-store.

Some products accumulate while others generate frequent breakages.

The FEFO system automates the release of products close to expiration, avoiding losses and returns.

Digital traceability guarantees complete visibility of batches and dates, ensuring compliance and regulatory control.

Predictive planning adjusts coverage according to rotation and margin, balancing the offer by category.

Campaigns increase demand without reaction time in replenishment.

Temporary consumption peaks leave leftovers that affect rotation.

Marketing, purchasing and operations work with disconnected data.

The promotional forecast anticipates the impact of each campaign and adjusts previous orders according to ideal coverage.

Post-campaign planning redistributes surpluses and activates intelligent liquidations by store or area.

Collaborative planning centralizes forecasts, promotions and stock in a single integrated platform.

The shelf does not allow a balanced exhibition between flavors, formats or brands.

The same product mix does not work the same in all locations.

The lack of history complicates initial forecasts.

The ABC-XYZ analysis prioritizes the most profitable products with the highest turnover, optimizing the available space.

Store planning adapts the assortment according to local consumer behavior.

Forecasting by analogy uses data from similar products to estimate initial demand and adjust replenishments.

Omnichannel inventory is not managed synchronously.

Omnichannel planning connects physical and digital stock, guaranteeing availability and avoiding duplication.

Late replenishments cause partial or off-route shipments.

Predictive planning consolidates orders and adjusts deliveries according to ideal coverage and frequency.

Promotions prioritize certain products, neglecting other essential ones.

Balanced planning adjusts coverage by family and profitability, avoiding breaks in base products.

Key indicators that offer a clear vision of the strategic weight that this industry has in the current and future global economy.

Data obtained from Statista*

Connect demand, procurement, and production through a modular cloud platform, designed to adapt to the unique needs of every industry.

Integration with all ERPs

100% Cloud, ISO 27001 Certification

Customer reviews

Measurable results

Ecosystem tailored to your needs

Quick implementation

Start with our demand module, the tool that allows you to calculate how much you will sell.

Add the features that suit your business. Scale at your own pace and expand when you need to, with our plugins.

Once you've added the features you need, get your price with our calculator. And if you have any questions, we'll sort them out for you.

Imperia gives you the functionalities you need and not those on the market, a solution that adapts and you pay for what you need. Pau Font, Supply Chain Manager at NOEL Alimentaria

Implementing the software with Imperia is a quick and straightforward process, starting with the integration of the demand module, and can be complemented with 2 new phases. Incorporating the purchasing module and the production module.

A process with full support from our team, with personalised training and consultancy.

Increase the accuracy of your predictions, bringing the expected demand closer to reality.

Minimizes inventory losses due to damage or expiration.

Savings in replenishment management time and stock management by point of sale.

Total Price:

€850,00

Schedule a meeting with our Supply Chain experts and discover the features that will make your supply chain a complete success.

Data controller: Imperia SCM Consulting, Ltd.

Purpose of processing: Manage your demo request and share information about our services.

Legitimacy: Consent granted by submitting the request form.

Recipients: There is no provision for communication to third parties, unless legally required.

Rights: Access, rectify and delete your data, as well as other rights explained in the Privacy Policy.