Irregular demand for materials and supplies

Usage spikes break patterns and distort forecast.

Implement adaptive forecast by region and spare part type to adjust forecasts to real demand.

150+ companies trust us

With customized configurations, variable demand and long supply times, forecast errors generate high costs. Connected planning provides visibility, balances capacity and demand, and allows you to quickly adapt to each project.

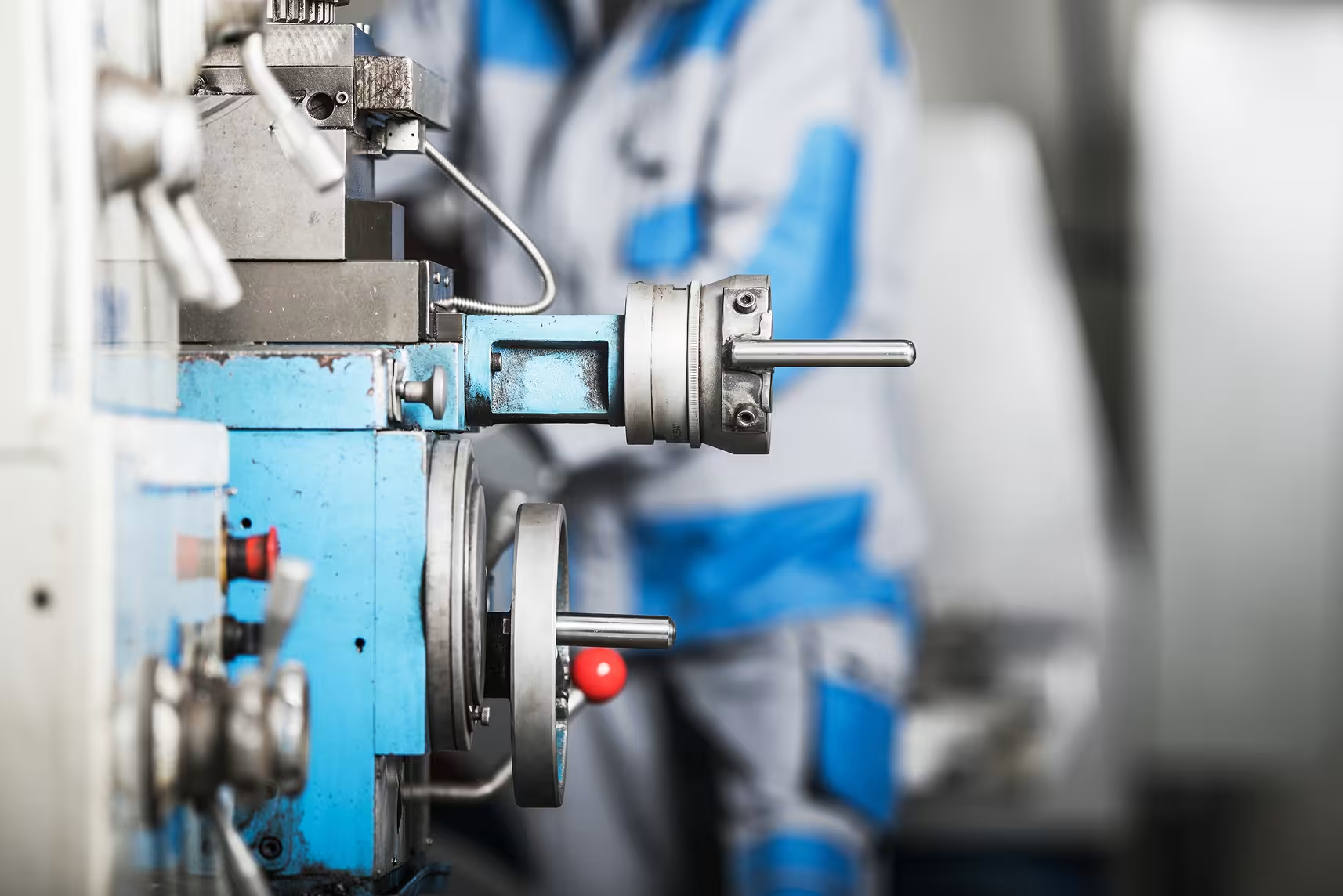

Machinery components and hydraulic systems take 90-180 days, making production planning and continuity difficult.

They make it difficult to balance stock and risk of downtime, affecting efficiency and operating costs.

Forecast changes generate obsolete material or line stops, affecting availability and planning.

Switch to the available supplier if the main one fails, ensuring continuity of supply.

Limits immobilized capital and avoids downtime, adjusting inventory to the criticality of the material.

Meet MOQs without generating excess inventory, optimizing costs and storage space.

Changes between batches of machinery and equipment generate delays and make production coordination difficult.

Extra reallocations, loss of OEE and overtime due to lack of capacity limitation.

Lack of realistic Gantt to plan prevents detecting overloads and adjusting priorities in a timely manner.

Realistic planning by line and plant, respecting availability of resources and execution times.

Minimizes setup minutes between batches, optimizing transitions and reducing stops.

Balances load without overloading the plant, ensuring efficiency and meeting deadlines.

Electronics, seals, adhesives and regulatory parts that expire or change specifications make their use difficult and generate obsolescence.

Blockage of capital and space in warehouses due to inventory that does not rotate, affecting efficiency and availability.

Difficult to clean up inventory before expiration due to lack of notices and proactive monitoring.

Detects excess and anticipates expiration dates to prioritize corrective actions.

Excludes lots that cannot be used, avoiding unnecessary purchases and losses.

Redistributes resources and avoids waste, optimizing inventory utilization.

Duplication of stock and urgent shipments due to incomplete information between warehouses.

Does not release capital or reduce delivery times due to lack of efficient redistribution of inventory.

Difficult to coordinate materials and critical parts between multiple locations, affecting efficiency and response times.

Coordinate each warehouse to improve efficiency and visibility throughout the network.

Automatically redistributes surpluses to free up capital and balance inventories.

Provides complete vision of the network to facilitate operational and strategic decisions.

Usage spikes break patterns and distort forecast.

Implement adaptive forecast by region and spare part type to adjust forecasts to real demand.

Forecast does not update codes or history.

Manage releases and replacements with automatic updating of codes and historical data to maintain accurate forecasting.

Safety cushions inflate foresight and reduce credibility.

Adjust forecasts by eliminating systematic biases and using historical data to improve accuracy and confidence in the forecast.

Key indicators that offer a clear vision of the strategic weight that this industry has in the current and future global economy.

Data obtained from Statista*

Connect demand, procurement, and production in one modular cloud platform, designed to adapt to the unique needs of any industry.

Integration with all ERPs

100% Cloud, ISO 27001 Certification

Customer reviews

Measurable results

Ecosystem tailored to your needs

Quick implementation

Start with our demand module, the tool that allows you to calculate how much you will sell.

Add the features that suit your business. Scale at your own pace and expand when you need to, with our plugins.

Once you've added the features you need, get your price with our calculator. And if you have any questions, we'll sort them out for you.

“We have managed to reduce the average DOT from 12 days to 7 and today we remove 80% of the lines from our warehouse.” Inazio Elorza, Supply Supply Chain Manager at Elesa + Ganter Ibérica

Implementing the software with Imperia is a quick and straightforward process, starting with the integration of the demand module, and can be complemented with 2 new phases. Incorporating the purchasing module and the production module.

A process with full support from our team, with personalised training and consultancy.

Increases the rotation of stored products, reducing costs and obsolescence.

Reduce shipping times, maximizing efficiency and reducing costs.

Improves the number of orders delivered in full and on time.

Total Price:

€850,00

Schedule a meeting with our Supply Chain experts and discover the features that will make your supply chain a complete success.

Data Controller: Imperia SCM Consulting, LLC.

Purpose of processing: Manage your demo request and share information about our services.

Legitimization: Consent granted by submitting the request form.

Recipients: There is no planned communication to third parties, unless legally required.

Rights: Access, rectify and delete your data, as well as other rights explained in the Privacy Policy.