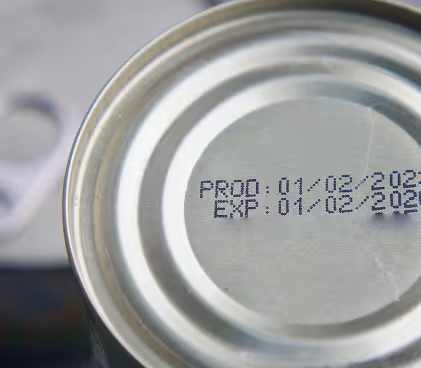

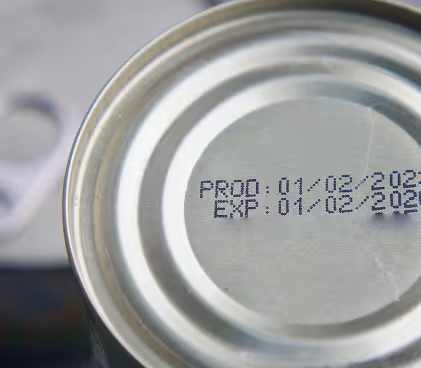

Uncontrolled expiration dates in old batches

The lack of batch control generates losses and returns.

Automated FEFO monitoring and expiration alerts anticipate risks and prioritize turnover.

150+ companies trust us

The demand for soups, broths and creams is highly seasonal and sensitive to promotions and consumption changes. Distributors must guarantee availability at all times without oversizing inventory or affecting profitability.

Demand increases drastically with the cold weather or during festive periods, generating consumption peaks that are difficult to predict.

The generic forecasts do not reflect the behavior by zone or channel.

The sudden decline after the high season generates immobilized workers and losses.

Predictive forecast analyzes historical weather patterns and recurring events to adjust demand in real time.

Granular planning by customer, product and location allows you to refine the forecast and avoid stockouts or overstocks.

Recalculate coverage at the end of the campaign, optimizing rotation and reducing waste.

Reactive purchases cause excess product and unnecessary costs.

Demand peaks generate partial or off-route shipments, affecting costs and service.

Without connection between sales, logistics and purchasing, decisions are made without operational context.

The integration between forecast and supply synchronizes purchases with real consumption and logistics capacity.

Predictive planning consolidates orders, guaranteeing punctual deliveries and reducing logistics costs.

Centralize information and generate proactive alerts in the event of deviations or risks of breakage.

The packaged product has a use-by date and requires constant management.

Returns or registration errors make it difficult to control the age of the stock.

The stock imbalance generates breakage in some areas and excess in others.

FEFO control automates rotation and prioritizes the dispatch of batches with a shorter shelf life.

Advanced traceability by batch and warehouse ensures full control and regulatory compliance.

Multi-level planning automatically redistributes product between centers based on regional demand and expiration date.

Retail campaigns cause unexpected consumption peaks and risk of breakage.

Promotions are planned without considering replacement or transportation capacity.

New flavors or formats lack history and make it difficult to calculate coverage.

The promotional forecast identifies trends and adjusts pre-launch stock to ensure availability.

Collaborative planning synchronizes commercial and logistics areas, aligning execution with actual availability.

Analogy forecasting uses sales of similar products to estimate initial demand and adjust replenishments.

The lack of batch control generates losses and returns.

Automated FEFO monitoring and expiration alerts anticipate risks and prioritize turnover.

Irregular delivery times affect the continuity of the service.

Predictive planning simulates alternative sourcing scenarios and consolidates orders by priority.

Partial deliveries raise costs and reduce operational efficiency.

Advanced planning groups compatible orders, optimizing transport occupancy.

Key indicators that offer a clear vision of the strategic weight that this industry has in the current and future global economy.

Data obtained from Statista*

Connect demand, procurement, and production in one modular cloud platform, designed to adapt to the unique needs of any industry.

Integration with all ERPs

100% Cloud, ISO 27001 Certification

Customer reviews

Measurable results

Ecosystem tailored to your needs

Quick implementation

Start with our demand module, the tool that allows you to calculate how much you will sell.

Add the features that suit your business. Scale at your own pace and expand when you need to, with our plugins.

Once you've added the features you need, get your price with our calculator. And if you have any questions, we'll sort them out for you.

"Imperia gives you the functionalities you need and not those on the market, a solution that adapts and you pay for what you need." Pau Font, Supply Chain Manager at NOEL Alimentaria

Implementing the software with Imperia is a quick and straightforward process, starting with the integration of the demand module, and can be complemented with 2 new phases. Incorporating the purchasing module and the production module.

A process with full support from our team, with personalised training and consultancy.

Increase the accuracy of your predictions, bringing the expected demand closer to reality.

Minimize inventory losses due to damage or expiration.

Optimize your plant's productive resources and increase its efficiency.

Total Price:

€850,00

Schedule a meeting with our Supply Chain experts and discover the features that will make your supply chain a complete success.

Data Controller: Imperia SCM Consulting, LLC.

Purpose of processing: Manage your demo request and share information about our services.

Legitimization: Consent granted by submitting the request form.

Recipients: There is no planned communication to third parties, unless legally required.

Rights: Access, rectify and delete your data, as well as other rights explained in the Privacy Policy.