Irregular demand by work phases

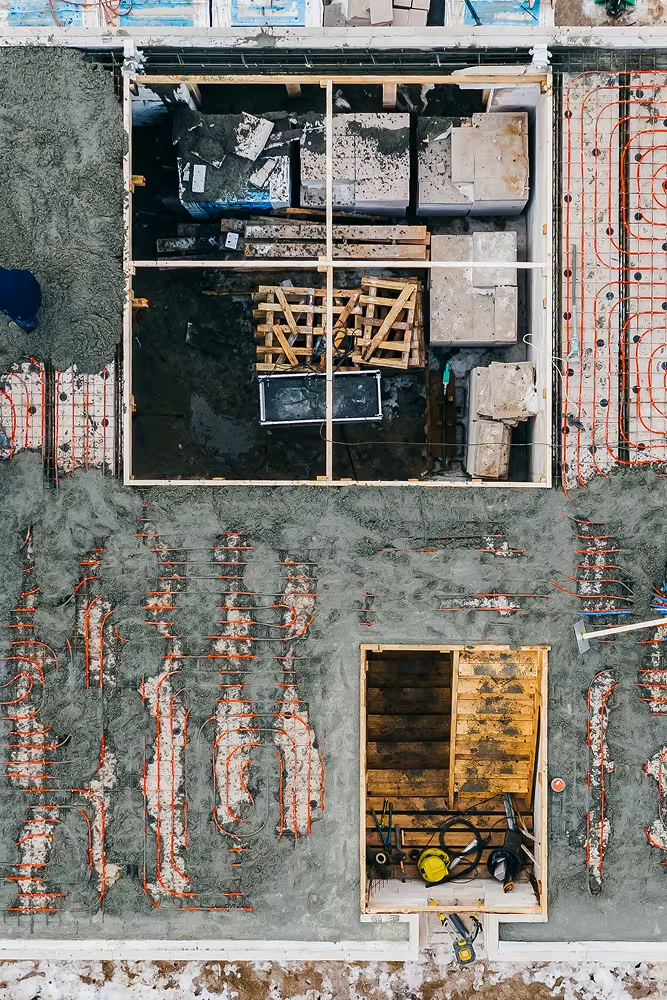

The need for materials changes according to the progress of each project.

The forecast by stage automatically adjusts demand according to the actual work planning.

Plus de 150 entreprises nous font confiance

Construction materials distribution companies operate in a highly demanding environment: simultaneous projects, tight deadlines and high-value materials. Lack of visibility or coordination between warehouses can lead to costly delays or excess inventory.

Global suppliers of cement, steel or machinery have unstable delivery times, which complicates planning.

High MOQs generate excess inventory and make it difficult to balance coverage and cost.

Variations in the pace of work cause imbalances in supply and stoppages.

Simulates alternative supply scenarios, prioritizing suppliers with immediate availability or safety stock.

Calculate optimal order point and consolidate purchases to meet MOQs without tying up unnecessary resources.

Dynamic forecasting updates demand by project based on actual progress, ensuring continuity of supply and reducing emergencies.

Lack of visibility of routes and priorities generates incomplete or late deliveries.

Excessive simultaneous orders cause bottlenecks in preparation and shipping.

There is no centralized delivery tracking or in-transit inventory control.

Prioritize deliveries according to urgency, distance and volume, optimizing routes and response times.

Balance the workload per warehouse, distributing orders based on capacity and operational availability.

The integration with ERP allows tracking of materials, transportation and deliveries, guaranteeing traceability and OTIF compliance.

Products purchased due to provision or excess coverage are immobilized and lose value.

Adhesives, chemicals or custom parts lose their usefulness if they are not used in time.

Obsolete or unused materials are not identified in a timely manner.

Analyze rotation and adjust coverage by type of material and work, freeing up space and capital.

Manage the rotation of sensitive materials and alert of upcoming expirations or technical incompatibilities.

The rotation and overstock report detects low output materials and proposes redistributions or liquidations to avoid losses.

Each center manages its inventory independently, generating duplication and lack of control.

The surpluses are not used between works or regions, which increases costs.

The supply of several works in parallel causes conflicts of priorities and lack of key materials.

Centralized management consolidates total stock and offers a single vision of the network, optimizing the flow of materials.

Multi-level inventory optimization allows moving low-turnover materials to areas with greater demand, reducing cost overruns and waste.

The demand planner distributes resources according to the criticality of each project, ensuring operational continuity in all active works.

The need for materials changes according to the progress of each project.

The forecast by stage automatically adjusts demand according to the actual work planning.

Design modifications alter anticipated material requirements.

Dynamic replacement management updates codes and forecasts in real time to avoid errors or waste.

The lack of integrated planning generates incomplete routes and logistical overruns.

Predictive planning groups deliveries by project and optimizes fleet utilization, reducing unnecessary transportation.

Key indicators that offer a clear vision of the strategic weight that this industry has in the current and future global economy.

Données obtenues de Statista*

Connectez la demande, les achats et la production au sein d’une plateforme cloud modulaire, conçue pour s’adapter aux besoins de chaque secteur.

Intégration avec tous les ERP

100% Cloud, Certification ISO 27001

Avis de clients

Résultats Mesurables

Écosystème adapté à vos besoins

Mise en œuvre rapide

Commencez avec notre module de demande, l'outil qui vous permet de calculer combien vous allez vendre.

Ajoutez les fonctionnalités qui s'adaptent à votre entreprise. Évoluez à votre rythme et étendez-vous quand vous en avez besoin, avec nos plugins.

Une fois que vous avez ajouté les fonctionnalités dont vous avez besoin, obtenez votre prix avec notre calculatrice. Et si vous avez des questions, nous y répondons.

"We have managed to reduce the average DOT from 12 days to 7 and today we remove 80% of the lines from our warehouse." Inazio Elorza, Supply Supply Chain Manager at Elesa + Ganter Ibérica

La mise en place du logiciel avec Imperia est un processus rapide et simple, qui commence par l'intégration du module de demande, et peut être complété par 2 nouvelles phases. En incorporant le module d'achats et le module de production.

Un processus avec un accompagnement total de notre équipe, avec des formations et des conseils personnalisés.

Optimize purchasing management, reduce costs and increase competitiveness.

Decrease the amount of products stored, reducing costs and increasing profitability.

Improve the number of orders delivered in full and within the established period.

Prix total :

€850,00

Planifiez une réunion avec nos experts en Supply Chain et découvrez les fonctionnalités qui feront de votre chaîne d'approvisionnement un véritable succès.

Responsable du traitement: Imperia SCM Consulting, S.L.

Finalité du traitement: Gérer votre demande de démo et vous partager des informations sur nos services.

Légitimation: Consentement accordé par l’envoi du formulaire de demande.

Destinataires: Aucune communication à des tiers n'est prévue, sauf obligation légale.

Droits: Accéder, rectifier et supprimer les données, ainsi que les autres droits expliqués dans la Politique de Confidentialité.