Mismatch between professional and private demand

Demand differs between professional and home DIY customers.

The segmented forecast analyzes purchasing patterns by type of customer and adjusts the stock of each category.

Plus de 150 entreprises nous font confiance

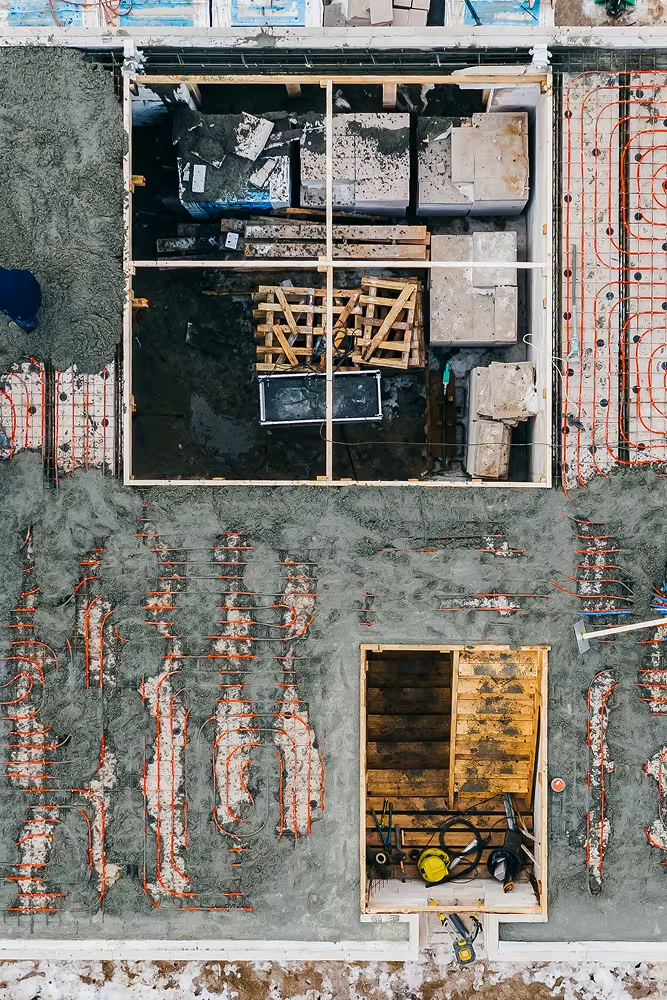

Retail stores of construction materials operate in a highly complex environment: high variety of products, marked seasonality and customers with unpredictable demands. Maintaining a balanced assortment, avoiding breakage and optimizing store space are constant challenges.

Sales fluctuate depending on the season or the type of project of the end customer.

The most in-demand items (cement, paint, tools) suffer frequent breakages.

There is no unified control that allows stock to be redistributed between points of sale.

Predictive forecasting anticipates demand by category and adjusts the coverage of each store according to seasonality and local trends.

AI models prioritize critical products and generate alerts automatic replenishment before stock runs out.

Multi-warehouse synchronization consolidates information in real time, allowing automatic transfers between stores or from the main warehouse.

Products with lower turnover take up valuable space in the store.

Excess Simultaneous orders cause bottlenecks in preparation and shipping.

Various items (cement, plaster, wood) generate high logistics costs.

ABC-XYZ segmentation classifies inventory by value and sales frequency, optimizing space and freeing up capital.

Predictive analysis recommends the optimal assortment by category, eliminating duplications and adjusting the supply to local demand.

Predictive planning evaluates the margin by product and adjusts coverage according to profitability and replacement frequency.

Promotions on tools or decorative materials generate unplanned peaks.

Promotional actions are not synchronized with the available inventory.

Campaigns leave surpluses that are difficult to liquidate.

The promotional forecast estimates demand by type of campaign and recalculates coverage, avoiding stockouts or overstock.

Collaborative planning connects marketing and purchasing to guarantee coverage before, during and after each campaign.

AI algorithms detect sales deviations and activate automatic redistributions or discounts by store.

In-store staff place orders based on intuition or limited history.

Delivery incidents are not detected on time.

Uncoordinated arrival of orders causes saturation and loss of control.

The predictive system automates orders according to real demand, minimum coverage and target service level.

Integration with ERP allows tracking of orders and deliveries in real time.

Planning synchronizes deliveries with the real needs of the store and the availability of staff for reception.

Demand differs between professional and home DIY customers.

The segmented forecast analyzes purchasing patterns by type of customer and adjusts the stock of each category.

Transportation and handling make the operation more expensive.

Planning algorithms optimize grouped deliveries and recommend minimum volumes per order.

Cost, turnover and margin data are not cross-referenced.

AI dashboards integrate sales, costs and losses, showing real profitability by family.

Key indicators that offer a clear vision of the strategic weight that this industry has in the current and future global economy.

Données obtenues de Statista*

Connectez la demande, les achats et la production au sein d’une plateforme cloud modulaire, conçue pour s’adapter aux besoins de chaque secteur.

Intégration avec tous les ERP

100% Cloud, Certification ISO 27001

Avis de clients

Résultats Mesurables

Écosystème adapté à vos besoins

Mise en œuvre rapide

Commencez avec notre module de demande, l'outil qui vous permet de calculer combien vous allez vendre.

Ajoutez les fonctionnalités qui s'adaptent à votre entreprise. Évoluez à votre rythme et étendez-vous quand vous en avez besoin, avec nos plugins.

Une fois que vous avez ajouté les fonctionnalités dont vous avez besoin, obtenez votre prix avec notre calculatrice. Et si vous avez des questions, nous y répondons.

We have managed to reduce the average DOT from 12 days to 7 and today we remove 80% of the lines from our warehouse. Inazio Elorza, Supply Supply Chain Manager at Elesa + Ganter Ibérica

La mise en place du logiciel avec Imperia est un processus rapide et simple, qui commence par l'intégration du module de demande, et peut être complété par 2 nouvelles phases. En incorporant le module d'achats et le module de production.

Un processus avec un accompagnement total de notre équipe, avec des formations et des conseils personnalisés.

Optimize purchasing management, reduce costs and increase competitiveness.

Reduces the amount of products stored, reducing costs and increasing profitability.

Improves the number of orders delivered in full and within the established time frame.

Prix total :

€850,00

Planifiez une réunion avec nos experts en Supply Chain et découvrez les fonctionnalités qui feront de votre chaîne d'approvisionnement un véritable succès.

Responsable du traitement: Imperia SCM Consulting, S.L.

Finalité du traitement: Gérer votre demande de démo et vous partager des informations sur nos services.

Légitimation: Consentement accordé par l’envoi du formulaire de demande.

Destinataires: Aucune communication à des tiers n'est prévue, sauf obligation légale.

Droits: Accéder, rectifier et supprimer les données, ainsi que les autres droits expliqués dans la Politique de Confidentialité.